Inherent Safety of LFP Battery Chemistry for Commercial Applications

Olivine Crystal Structure: How It Inhibits Oxygen Release and Thermal Runaway

At the heart of why LFP batteries are so safe lies their olivine crystal structure, which has the chemical formula LiFePO4. What makes this structure special? Well, the iron phosphate lattice holds onto oxygen atoms really tightly. So tight in fact that we don't see much oxygen escaping even when temperatures climb past 500 degrees Celsius. Compare this to those layered oxide cathodes found in nickel based batteries like NMC or NCA, and things get interesting. Those other structures tend to fall apart under stress from overcharging, physical damage, or just being exposed to extreme heat. Now here's what matters most for safety: oxygen release fuels thermal runaway, that dangerous chain reaction that can lead to fires. Since LFP doesn't let go of its oxygen easily, it basically cuts off one of the main ways fires could start. That's why these batteries work so well in places where safety is absolutely critical, think about densely packed city buildings, massive data centers running non stop, or factories where any kind of fire risk would be totally unacceptable for both people and expensive equipment.

Thermal Stability Benchmark: LFP vs. NMC/NCA — Onset Temperatures and Exothermic Heat Generation

The thermal stability of LFP chemistry stands out better than both NMC and NCA options, something that standard abuse tests have repeatedly shown. Most NMC and NCA battery cells start going into thermal runaway around the 150 to 200 degree Celsius range, but LFP materials stay stable much longer, holding up until about 270 to 300 degrees Celsius. That means there's roughly a 100 degree safety buffer difference between these chemistries. And here's another important point: even if something goes wrong with an LFP cell, it doesn't release nearly as much energy during failure events compared to other battery types, which makes failures generally less catastrophic in real world applications.

| Parameter | LFP | NMC/NCA | Safety Impact |

|---|---|---|---|

| Onset Temperature | ~270°C | ~150–200°C | Wider operational safety margin |

| Exothermic Energy | <100 kJ/mol | >200 kJ/mol | Lower fire propagation risk |

| Oxygen Release | Negligible | Significant | Reduced combustion fuel source |

This combination—delayed onset and lower heat generation (roughly half that of nickel-based chemistries)—gives protective systems more time to respond and dramatically reduces the likelihood of fire spread in commercial battery storage deployments.

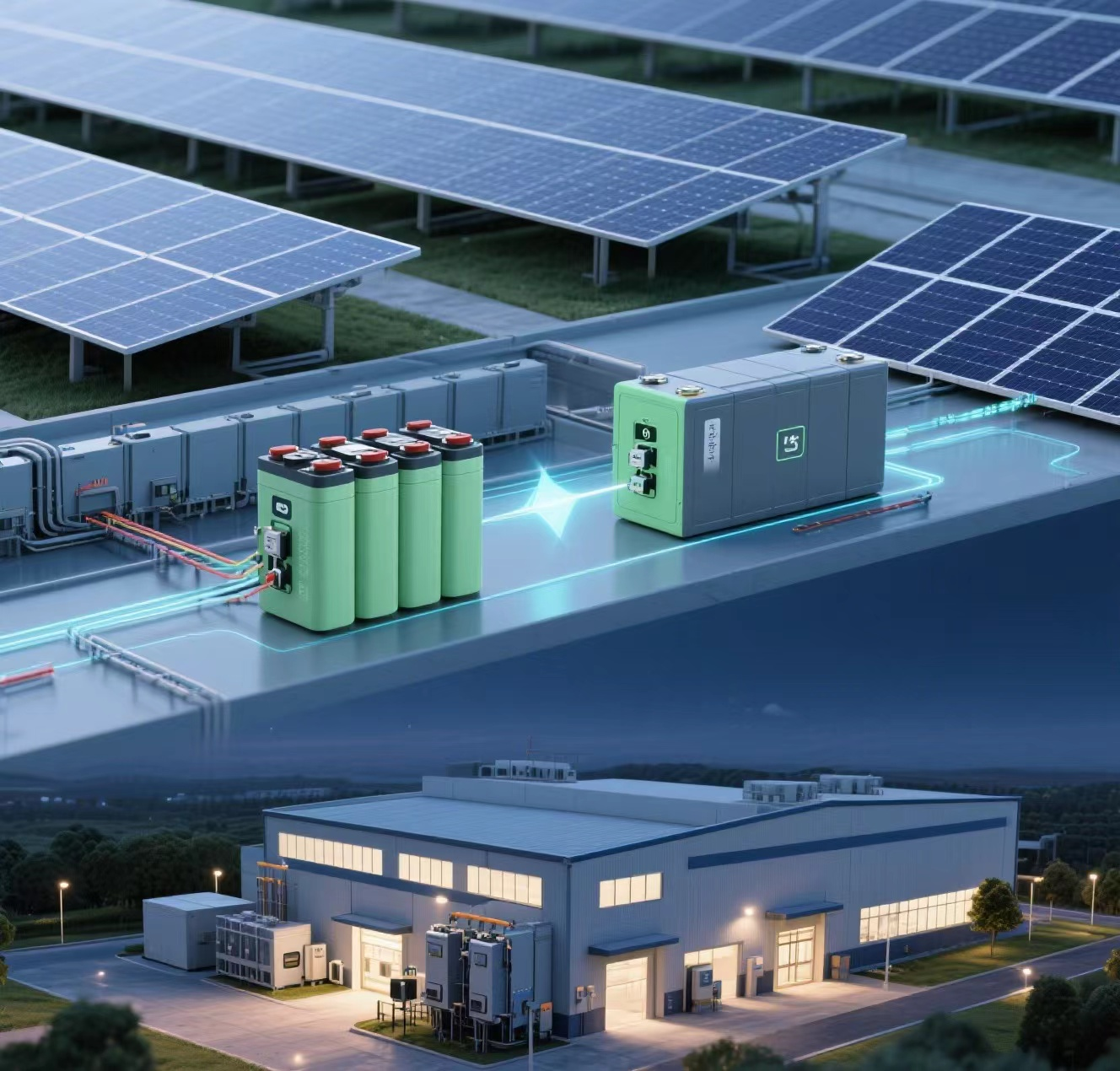

System-Level Safety Engineering in Commercial LFP Battery Storage

While LFP's intrinsic stability is foundational, real-world commercial applications require robust system-level engineering to manage residual risks—including electrical faults, ambient temperature extremes, and mechanical stress. Leading manufacturers integrate validated thermal controls, structural containment, and regulatory-compliant enclosure design to exceed baseline safety expectations.

UL 9540A-Validated Thermal Management: Passive Design, Active Cooling, and Cell-Level Quenching

UL 9540A-validated thermal management employs three complementary layers:

- Passive design, using phase-change materials to absorb transient heat spikes without power input;

- Active cooling, via liquid or forced-air systems, maintaining optimal cell temperatures between 15–35°C across varying load and ambient conditions;

-

Cell-level quenching, which rapidly suppresses localized thermal events before propagation occurs.

Together, these strategies have been verified under extreme abuse conditions—including nail penetration and external heating—to contain failures within individual cells, preventing cascading thermal runaway across modules.

NFPA 855—Compliant Enclosure Strategies: Ventilation, Isolation, and Fire Containment for C&I BESS

Commercial and Industrial Battery Energy Storage Systems (C&I BESS) must comply with NFPA 855, which mandates engineered enclosures designed to mitigate escalation risks. Key features include:

- Explosion-ventilated panels that safely direct off-gas emissions away from personnel and adjacent equipment;

- Fire-rated compartmentalization—battery stacks isolated every 20 kWh to limit fire spread;

- Ceramic thermal barriers that delay conductive heat transfer to surrounding structures for over two hours.

Field performance data from more than 12,000 compliant installations shows a 98% reduction in fire-related incidents compared to non-compliant configurations, reinforcing the value of code-aligned physical safeguards.

Operational Safety Protocols Unique to Commercial LFP Battery Storage

Multi-Layer Protection: BMS-Driven Overcurrent, Insulation Monitoring, and Mechanical Resilience

Commercial LFP battery storage relies on a triad of interdependent operational safeguards—each independently validated and collectively coordinated through an advanced Battery Management System (BMS):

- Overcurrent and voltage monitoring: Real-time detection of anomalies triggers immediate circuit isolation, preventing short-circuit-induced thermal overload;

- Insulation resistance monitoring: Detects ground faults as low as 0.5 mA—critical for humid, dusty, or saline-rich industrial environments where leakage paths are common;

-

Mechanical resilience: Vibration-dampening mounts, crush-resistant enclosures, and seismic bracing preserve structural integrity under transport, installation, and long-term operation.

These protocols meet UL 1973 requirements for stationary energy storage and collectively achieve a field-validated 99.99% failure prevention rate in commercial deployments—ensuring both safety and operational continuity.

Field-Proven Safety Performance of LFP Battery Storage in Real Commercial Deployments

The reliability and safety record of LFP battery storage keeps getting stronger across all sorts of commercial settings, whether it's massive grid substations or those lonely telecom towers out in the middle of nowhere. When big storms hit and power grids go down—think hurricanes or those brutal winter blizzards—hospitals and emergency centers with LFP backup systems kept running for over 96 straight hours without any problems. No fires, no overheating issues at all. Most of these installations regularly clear the tough UL 9540A fire tests and meet all the requirements set by NFPA 855. Looking at the bigger picture, the whole industry sees failures happening less than once per 10,000 units since 2021. Telecommunications companies tell similar stories too. Their network towers around the world (we're talking about 15,000 plus locations) haven't had a single instance of thermal runaway. They credit this impressive track record to how well LFP batteries handle extreme temperatures, can be deeply cycled many times, and still work fine even when left on charge for long periods. All these real world experiences show clearly that LFP isn't just safer on paper—it actually performs better in the messy, unpredictable conditions that commercial energy storage faces every day.

FAQ about LFP Batteries

Why are LFP batteries considered safer than NMC or NCA batteries?

LFP batteries have an olivine crystal structure that tightly holds oxygen atoms, reducing the risk of oxygen release and thermal runaway, which are major fire hazards in other battery types like NMC or NCA.

What is the thermal stability advantage of LFP batteries?

LFP batteries can withstand temperatures up to 270-300 degrees Celsius compared to NMC/NCA batteries, which start thermal runaway at 150-200 degrees Celsius. This provides a significant safety buffer.

What role does the Battery Management System (BMS) play in LFP battery safety?

BMS provides real-time monitoring of overcurrent and voltage, insulation resistance, and ensures mechanical resilience, adding multiple layers of protection that complement the intrinsic stability of LFP chemistry.

How is compliance with standards like UL 9540A and NFPA 855 ensured?

LFP battery systems are designed with validated thermal management and compliant enclosures to meet these stringent industry standards, drastically reducing fire-related incidents in commercial deployments.

Table of Contents

- Inherent Safety of LFP Battery Chemistry for Commercial Applications

- System-Level Safety Engineering in Commercial LFP Battery Storage

- Operational Safety Protocols Unique to Commercial LFP Battery Storage

- Field-Proven Safety Performance of LFP Battery Storage in Real Commercial Deployments

- FAQ about LFP Batteries